A recent article published by Reuters describes the challenges facing the biotech industry with respect to the scaling of manufacturing processes for cell and gene therapies. The article focuses on some key recommendations to make these processes more efficient and scalable.

Its recommendations include:

- taking a manufacturing-first approach,

- flexible end-to-end facilities, and

- the development of a collaborative ecosystem

These are sensible recommendations, especially for therapies where the process is the product.

We believe that the last recommendation, the development of a collaborative ecosystem, is critical. And, it is about more than just the integration of equipment. There is a need for novel digital platforms that allow for the aggregation, organization, and contextualization of development data and information. Multiple dimensions of information need to be tracked over time to build process understanding and intelligence.

These collaborative pathways of working and sharing data need to be right, the first time. It can’t be assumed that they’ll be bolted on in the future because the development of these therapies is too complex.

The requirements of quality and regulatory compliance mean that process development and later validation activities must conform to the best practices outlined in various guidelines including ICH, ISO, PIC/S, etc. However, process scientists and engineers often leave this to the regulatory and quality consultants requiring additional streams of work to align previous activities with the existing requirements. Harmonizing ways of working and collaboration shouldn’t be the job of regulatory or quality. It needs to be designed into the development process from the start.

Significant efficiencies can be realized if digital platforms are available that guide development activities with compliance in mind from the beginning. Furthermore, if best practices such as quality-by-design and data-integrity-by-design are inherent to the digital platform, then process understanding can be developed holistically over time using data and sound scientific rationale.

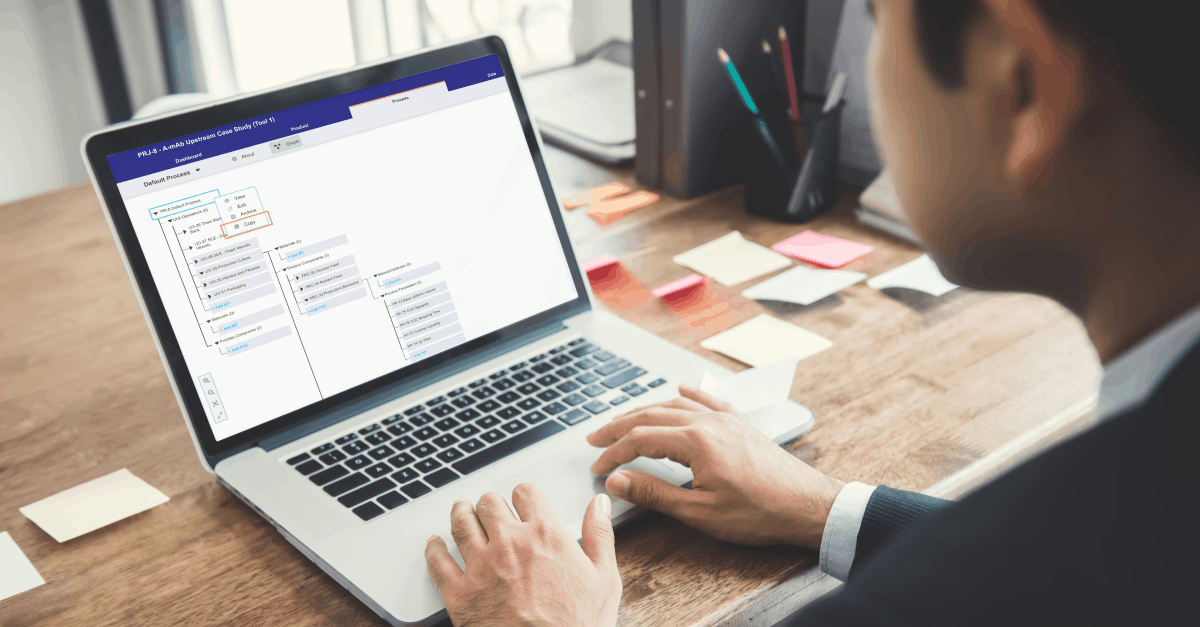

We recently published a case study that describes how one of our customers used the QbDVision platform to begin their digital journey for product lifecycle management for a CGT application.

All of the article recommendations require an enabling element: people. And, for the modern biotech company developing a novel therapy, their people are strapped for their most precious resource – time. A structured data platform like QbDVision brings integration and visibility with automated compliance to complex manufacturing processes like those for CGT applications. It helps people to get back that precious resource, and it can go a long way toward activating the recommendations presented in the referenced article and getting a complex process “right the first time”.