Companies developing and manufacturing biologics are heavily focused on product quality metrics to ensure patient safety and efficacy.

They are equally focused on the optimization of these manufacturing processes to maximize the output per batch. Upstream processes seek to maximize titer while downstream processes look to maximize yield.

Process development teams need to track the evolution of their process performance just as they do their product quality. That job just got a whole lot easier.

What’s Changing

We are introducing a new variable type in QbDVision called the performance attribute. Performance attributes can be defined for the final product, final performance attribute (FPA), and for any intermediates during the manufacturing process, intermediate performance attribute (IPA).

Example Use Case

When manufacturing biologics, the upstream process moves through multiple cycles of seed culture expansion (SCE) before the final production culture unit operation. For each cycle of SCE before the production culture, it is common to monitor process performance attributes such as peak viable cell concentration (VCC), %Viability at Cell Passage, and Culture Duration. With the availability of the performance attribute variable type, these attributes can be defined and tracked as IPAs for each SCE operation. At the production culture stage, the final titer can be defined as an FPA, and the IPAs linked to this FPA.

Why is this happening?

It is not uncommon to see process parameters that optimize titer/yield have an adverse effect on product quality and vice versa (example). Therefore process development teams need to track performance attributes of the process separately from quality attributes of the product to find the best balance when needed. The new functionality supports this discussion with better clarity. Quality attributes are technically separate from performance attributes and should be described and assessed for risk separately.

How do I use it?

The introduction of the performance attribute (PA) variable type was carefully considered so that it would fit seamlessly within the “best practice” workflows already designed into QbDVision.

Final performance attributes (FPAs) can be defined in the Product→ QTPP section of QbDVision along with General Attributes and Final Quality Attributes.

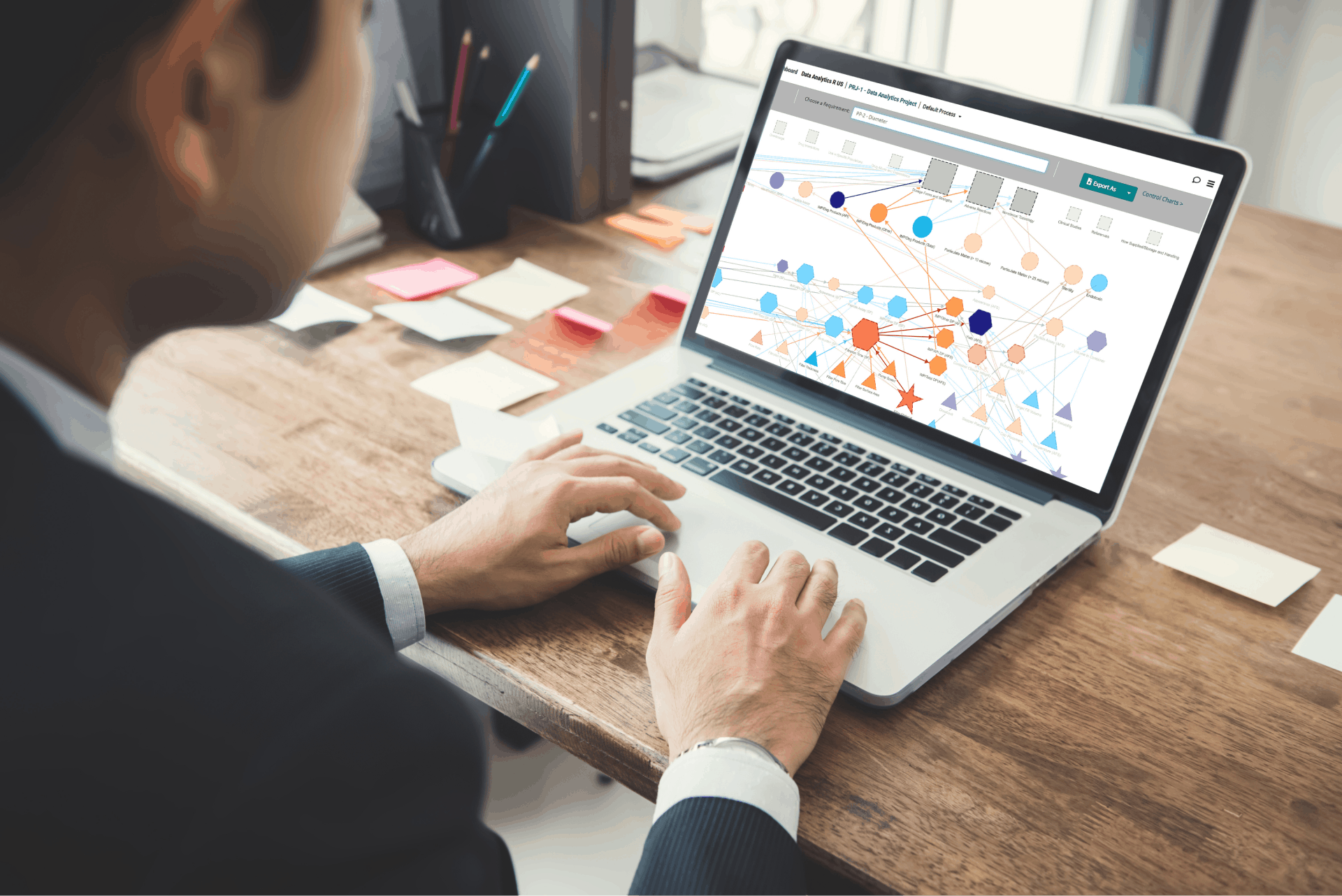

Intermediate performance attributes (IPAs) can be defined with the Process Explorer User Interface as shown below:

Quality risk management is integrated into all QbDVision workflows, so the use of the PA type will start with the Risk Management Plan if you are using separate risk schemas for each variable type.

Availability

Multiple processes support is available today in our standard and sandbox environments. Our validated product customers will see them in the Electronica release, expected in February of 2021.